Micromachining is the procedure of creating very small and extremely intricate structures with high precision. This technology has transformed the manufacturing of microelectromechanical systems (MEMS) and is used in a range of devices, including smartphones, medical equipment, and automotive sensors.

Complex Shapes and Features

One of the main advantages of micromachining is its ability to create complex shapes and features on a very small micrometre scale. This permits for the creation of intricate designs that would be impossible to achieve with traditional machining methods. Micromachining can also be used to create features with high aspect ratios, which is particularly useful in the manufacturing of microfluidic devices.

High Precision

Micromachining also offers high precision, which is crucial in the manufacturing of micro-scale devices. Traditional machining methods can be challenging to achieve the required level of accuracy, but micromachining allows for precise control over the size, shape, and position of each feature. This level of precision is essential in the manufacturing of MEMS where even minor discrepancies can significantly affect performance.

Speed and Efficiency

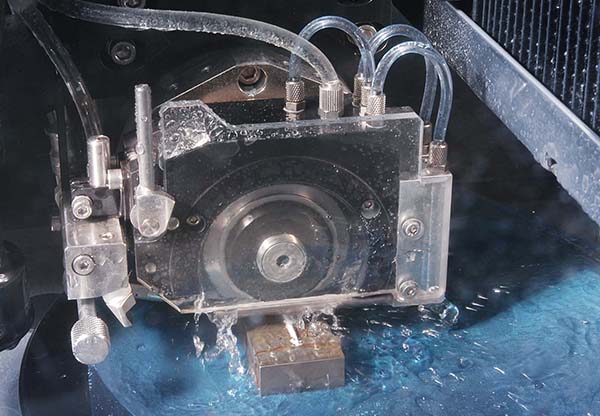

With the latest advances in micromachining technology, great improvements in speed and efficiency have been created. New techniques, such as laser micromachining and micro-electro discharge machining (micro-EDM), have made it achievable to produce complex features quickly than it would take with traditional methods. These innovations have also made micromachining more accessible to smaller manufacturers who may not have the capital to invest in expensive equipment.

Examples of Micromachining used in various Sectors

- Micromachining is used in the medical sector for the manufacturing of surgical instruments, implants, and diagnostic devices.

- Micromachining is used in the manufacturing of microelectromechanical systems (MEMS) for use in aerospace applications for navigation, sensing, and control of aircraft systems.

- Micromachining is used in the automotive sector for the manufacturing of automotive sensors, a critical component in modern vehicles.

- Micromachining is used in the electronics sector for the manufacturing of microprocessors, microcontrollers, and other electronic components.

The Future of Micromachining

As micromachining is becoming an essential tool in the manufacturing of micro-scale devices, new technological advancements are changing micromachining. As the field continues to progress, we can expect to see even more exciting progressions in the future. Research in the field are investigating new materials and techniques and pushing boundaries of what is achievable. In the coming years, we can expect to see even more innovative and ground-breaking technologies emerging as a result of this precision manufacturing technology.

Micromachining has transformed the manufacturing of micro-scale devices by providing the ability to produce complex features with high precision and efficiency. With continued advancements in the field, we can expect to see even more exciting developments in the future.

For all your Micro Machining services you require please contact us here