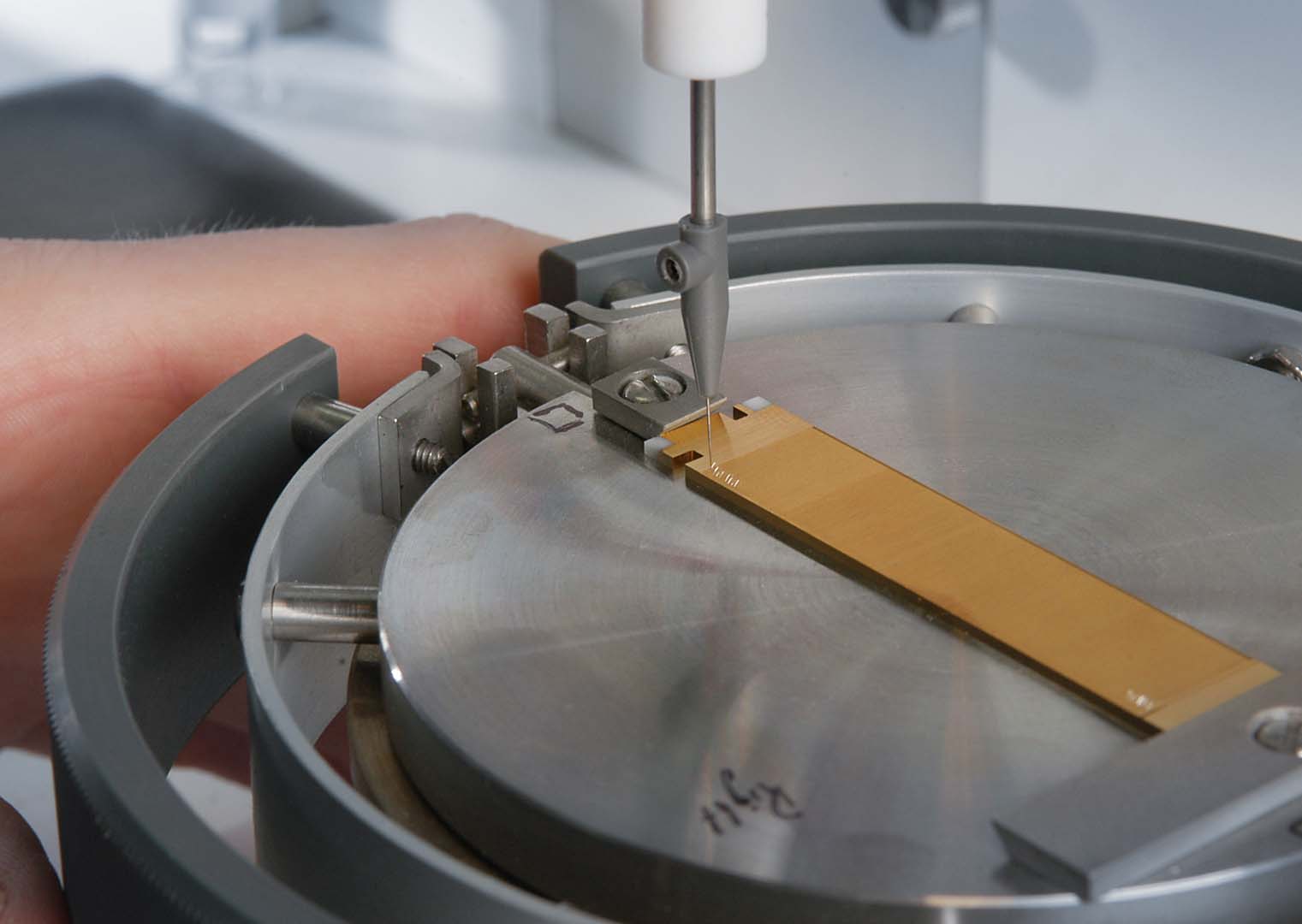

Wire Bonding

Aluminium or gold wedge bonding

ICT has two manual wire bonding machines at its micro component manufacturing facility in Shepperton. These can be used for either aluminium or gold wedge bonding.

Manual wire bonding is a cost-effective option for small batch production. Manual wire bonding services provided by ICT are also favoured for new product design and prototyping, where it is useful to test a variety of wire types, wire sizes and encapsulation materials.

ICT’s design expertise

ICT has considerable experience of working with clients to make product improvements, either at the new product design stage or later in a product’s life cycle. The design expertise provided by ICT engineers often results in a reduction of costs, improved reliability or greater longevity of clients’ products.

ICT engineers enjoy the technical challenge of working with clients to create or improve products – a service that clients welcome and appreciate. Please contact us for more information on our design services.

The Wire Bonding process

Ultrasonic welding

Wire bonding is used to interconnect components and conducting tracks. The method used by ICT is ultrasonic welding.

Tailored Wire Bonding solutions

ICT’s wire bonding services are individually tailored to suit each client’s specific requirements. While ICT’s solutions to its clients’ requirements may vary, the quality of ICT’s manufacturing, the reliability of its wire bonding services and the dedication of staff, ensure it consistently meets the highest delivery standards.

The care taken to meet or exceed customer expectations throughout every stage of a project is what makes ICT exceptional.

Wire sizes

ICT can work with wire sizes ranging from:

- Gold – Diameters from 15 to 75 microns

- Aluminium – Diameters from 20 to 75 microns

Want more information or a quote?

If you have a wire bonding job that you would like to discuss with an ICT engineer,,

please call us now on +44 (0)1932 509911.