Quality assurance

Committed to manufacturing precision components to the very highest standards

Quality assurance

ICT is committed to manufacturing precision components to the very highest standards. Stringent quality audits are routinely performed throughout ICT’s manufacturing and product assembly and we are very proud of recording a long and unbroken history of zero non-conformances.

What sets ICT apart is the time we take to understand, and fully meet, the needs of our customers. Quality assurance personnel, working closely with in-house design and quality engineers, ensure that appropriate manufacturing and inspection processes are undertaken in order to guarantee success.

Product improvements

The close working relationship between ICT and its customers continues throughout a product’s life cycle. In addition to achieving excellence in manufacturing and quality, the ongoing and proactive support offered by ICT often leads to innovative and highly valued product improvements.

Inspection and testing

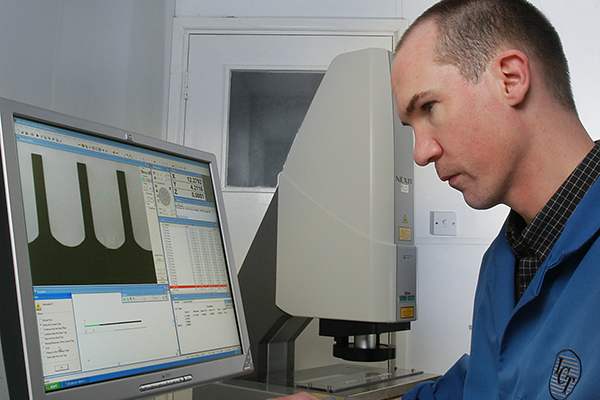

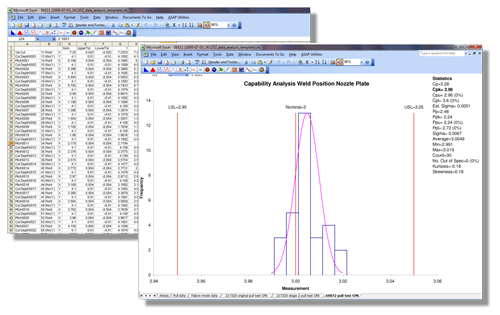

ICT’s quality assurance team is experienced in a variety of quality methods. All measurement and inspection data is recorded and data can be extracted into a variety ‘readable’ report, or more basic ‘data’ formats, which can be provided to customers with shipments, or on request.

ICT’s inspection processes include:

- Nikon Nexiv Vision measuring systems, with Renishaw touch probes. Programming includes min/max tolerances, and the system instantly flag measurements outside of these parameters to the operator

- Dage pull testing of wire bonding, and vapour deposition adhesion

- Heidenhain vertical comparitor

- Pressure testing of laser welded components

- Temperature cycling

- Electrical testing of flexible circuits using Cirris tester

- Electrical testing using component testers, Megger or multimeters

- Traditional measurements using micrometers and callipers

- Various visual inspections using microscopes and visual comparison standards.

Certification

ICT has been assessed and registered by NQA against the provisions of BE EN ISO9001:2015 for precision component manufacture and assembly for the commercial inkjet printing industry. ICT is also fully aware of relevant legislative requirements and advises on appropriate materials and processes where applicable.

Want more information or a quote?

If you would like further information or a quote please complete the enquiry form or call now on+44 (0)1932 509911.